Did the U.S. Food and Drug Administration cause the infant formula shortage? FDA inspection records show how the agency may have had its finger on the scale in deciding to shut down the Abbott Labs plant in Sturgis, Michigan, causing the major supply chain crisis for families across the country. These exclusive documents show widely varied differences in how the FDA handled inspections at Abbott compared to similar violations at a competitor.

During a congressional hearing on May 18, neither Democrats nor Republicans questioned the agency’s judgment in its February order shutting down an Abbott Labs plant in Michigan, which had been producing 35 percent of the nation’s supply of formula for infants, including a majority of the country’s specialty formulas for children with digestive ailments.

Rather, the panel and the media have focused on an anonymous whistleblower — a disgruntled former employee of the plant who was terminated by Abbott in August 2020 – and the timing of when FDA investigated the whistleblower’s allegations.

The Wall Street Journal reports that the ex-employee first complained in February 2021 to the U.S. Occupational Safety and Health Administration (OSHA), and cited “a host of problems at the company’s Sturgis plant…”

The employee also had filed a discrimination complaint with the Michigan OSHA. Abbott and FDA were informed immediately of both, according to the Journal. Abbott said it investigated and found no substantiation and reported that to authorities.

Abbott said the employee, whose identity was not disclosed by the Journal, “continued a pattern of ever-evolving, ever-escalating allegations” during the coming months.

Later that fall, four infants who had consumed the firm’s EleCare specialty formula got ill with Cronobacter sakazakii and two babies died. The FDA then asked the Centers for Disease Control and Prevention to test samples of milk from the Sturgis plant.

According to a report by the Oversight and Investigations Subcommittee of the House Committee on Energy and Commerce, which held the May 18 hearing, “none of the five strains found in environmental samples matched the two patient samples that CDC analyzed.”

Abbott has maintained for months that there was no Cronobacter in its milk products. But in testimony to the House panel, FDA Commissioner Robert Califf, M.D., said “we cannot confirm the formula caused the illness or death or rule it out.” In other words, the FDA had, and has no proof to this day, that the bacteria that affected the infants were linked to the Sturgis plant.

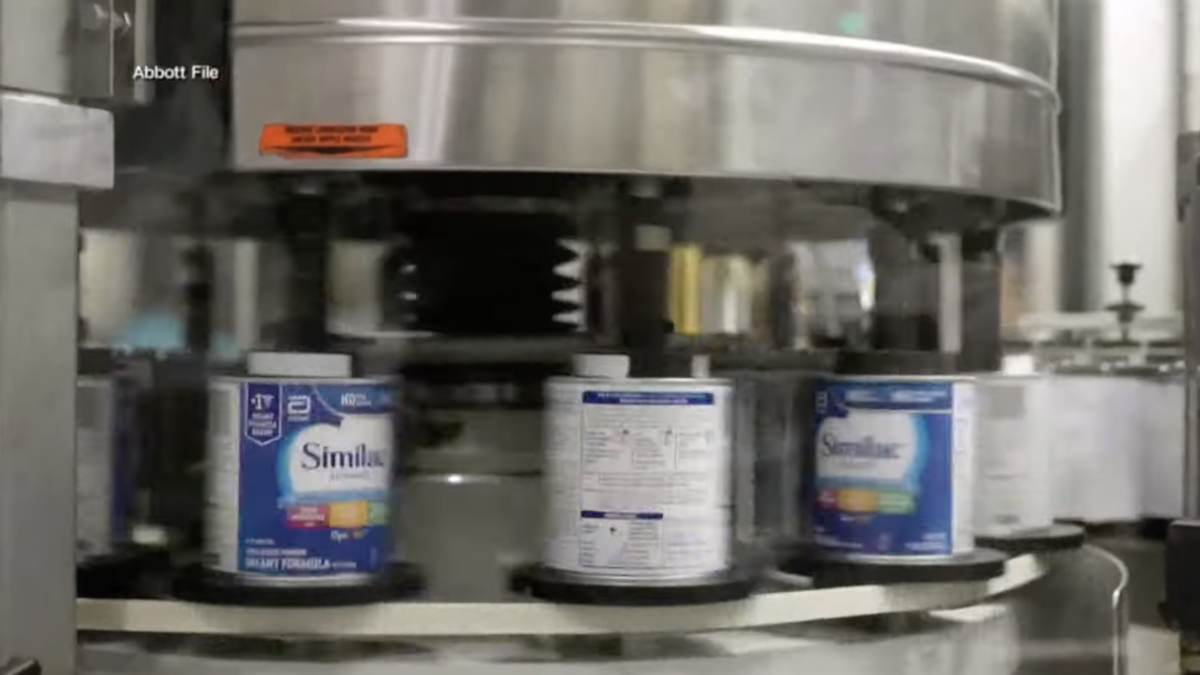

On Jan. 31, 2022, 12 FDA auditors — an unprecedented number for this type of investigation — stormed into the Sturgis plant facility, auditing until March 18. The agency for the second time in months issued Abbott a 483 – a formal bill of violations — and the company recalled the affected lots.

The violations included water leaks, standing water on the floor, employees not wearing appropriate gear, and of course, “the presence of Cronobacter sakazakii in medium and high care areas of powdered infant formula production.”

On Feb. 19, before the inspection even concluded, FDA released a warning to parents to not use the products from the affected lots of Elecare, Similac, and Alimentum. The agency ordered the plant shut until Abbott could make corrections. The shortage then ensued.

A day before the House hearing, Abbott agreed to a “Consent Decree,” which compels it to meet certain FDA requirements to reopen. The Sturgis plant resumed production on June 4. Like a number of big companies, Abbott sought to comply with FDA rather than fight the agency.

In this reporter’s 35 years analyzing FDA inspections, including 30 years publishing newsletters for an FDA trade news source, it seems the FDA overreached with Abbott this go around because the company had 483 violations in 2019 and 2021. When the agency got wind of whistleblower allegations, they went overboard.

Generally, large corporations like Abbott do not fight the FDA. They seek to comply, and the agency is not required by law to account for infant formula shortages like it is for human drugs.

But Califf, who said the Abbott violations were “egregious,” was never asked during the hearing how FDA has handled other infant formula audits, although the CEOs of those companies were present for questioning.

Consider the 2012 audit of another formula manufacturer that was connected to reports of “infants who tested positive for Cronobacter.” Documents in the files of FDAinfo.com show that Mead Johnson Nutrition’s plant in Evansville, Illinois had numerous deficiencies, including the presence of Cronobacter and two infant deaths in 2011 tied to the bacteria. The plant got a 483 in 2017, in part, for Cronobacter in the facility.

Yet the agency did not request a recall nor order a shutdown following either inspection. A 2012 article in the trade newsletter “Food Navigator” claimed, “there is no need for a product recall … as part of an investigation into four babies infected with the bacteria – two of whom have died.”

Inspection records of the Evansville factory state “there were 91 serious events” involving infant formula from Jan. 1, 2010, to Dec. 31, 2011. These included cases of babies “hospitalized and diagnosed with a bacterial infection,” and one hospitalized “and treated for salmonella.” But the FDA’s conclusion was not to shut down the plant. They wrote: “All complaints appear to be addressed sufficiently. No deficiencies were reported.”

The Commerce oversight subcommittee had copies of these inspection records before the May 18 hearing, but never inquired about them. By May 8, according to the Oversight and Investigations Subcommittee panel report, some 43 percent of infant formula SKUs were sold out at major retailers across the nation and the Biden administration was frantically importing formula from abroad.

In essence, the FDA created a worse problem than what it tried to solve due to regulatory tunnel vision and making a leap that the Cronobacter that killed the infants was the same that was in the Sturgis plant.

The Abbott EleCare shortage has been the most problematic, especially for parents with babies and toddlers who cannot process amino acids in proteins. Abbott said in a news release that EleCare is the first to be produced in the reopened Sturgis plant, and “there should be enough to fulfill current patient needs until new product is available in the coming months.”

Now, the HHS Inspector General is investigating how the FDA handled the ordeal. “Specifically, we will review FDA’s actions leading up to the infant formula recall at the Abbott facility in February 2022 to determine whether FDA followed applicable policies and procedures to: (1) conduct inspections of the manufacturing facility and (2) oversee Abbott’s initiation of the infant formula recall,” the I.G. news release stated. It is hoped the I.G will examine inspection consistency, why FDA relied so much on the whistleblower complaint, and if higherups in the Biden administration were involved.

Perhaps Congress should require FDA to report annually on medical food shortages as it required in 2012 for human drugs, and maybe for medical device shortages, too. There is currently a shortage of breathing machines (CPAP/BIPAP) for sleep apnea patients due to a recall by the firm Philips Respironics, which was triggered by an adverse FDA inspection in June 2021.

An agency spokesperson did not return emails seeking comment on this article.